Scilogs – From Nature to Nurture

Original Story: SciLogs – From Nature to Nurture

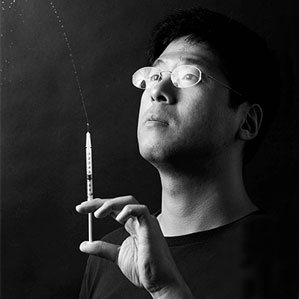

One late evening in a coffee shop near McGill University, Jeff Karp overheard two students talking about drug delivery and tissue engineering. Jeff, an undergrad, listened closely as the students discussed two graduate level courses. At the time Jeff was questioning his major. He had switched from biology to chemical engineering but found himself bored in class; uninterested in the details of how refrigerators work. That night at the coffee shop Jeff learned about two classes that he became desperate to take: one on artificial organs and engineering and the other on cells and biotechnology. To enroll he would need to take no less than 5 prerequisite physiology classes. Undeterred, Jeff added a year to his undergrad studies and switched majors yet again, this time to biomedical engineering. He had finally found the right balance between medicine and engineering. Jeff says a “degree in engineering is a degree in problem-solving” and that he uses the skills he learned in undergrad every day.

In 2008, Jeff and Langer published a paper in PNAS describing a new type of waterproof adhesive based on the way gecko feet stick to surfaces. The technology is a mix of “topography and chemistry,” says Jeff, describing how they mimicked gecko feet by creating a thin layer of reactive tissue embedded within the unique peaks and valleys that gecko feet use to stably cling to their environment. A problem remained. Using reactive chemistry for adhesion can promote inflammation, not an ideal property for a bandage.

Jeff, now an associate professor at Harvard Medical School and Co-Director of the Center for Regenerative Therapeutics at the Brigham and Women’s Hospital, began considering what examples from nature they could use to make a better adhesive without promoting inflammation. Turning to the literature and even google, what Jeff and his colleagues stumbled upon was the humble porcupine. A slow moving creature with powerful quills, Jeff was surprised to find that no one had described the force behind this protective structure. Published in PNAS last month, Jeff and his team found that that the tiny barbs which cover the tip of porcupine quills facilitate a 50% reduction in the force required to penetrate skin compared to quills without the characterisric barbs. Once the quills have penetrated tissue, however, they are exceedingly difficult to extract. Creating an artificial model of the porcupine quill, Jeff and his team believe it has potential as a new class of adhesive material and needles.

Jeff’s group, unlike many labs, is careful to analyze the clinical, regulatory, and funding potential of all potenital projects. This is because his group is motivated to pursue only those technologies that can be rapidly brought to the clinic. He explains this motivation by saying, “It’s easy to develop technology and it’s easy to find problems to work on but what’s difficult is to match technology to a problem.” Jeff believes the “onus is on those working upstream to think critically and channel resources to bringing translational technology.”

By creating a diverse team that includes immunologists, chemical engineers, clinicians, and polymer chemists, Jeff is creating an interdisciplinary approach to biomedical engineering all in his own lab. His team gets their inspiration from the zoo, the aquarium, cactus farms, and yes, even google searches. So how long will it be until your next injection is given with a less painful porcupine-inspired needle? Jeff hopes that the technology will be able to move into clinical trials in the next 3-5 years, remarking on the sway that resources have on bringing a new technology to the clinic. Jeff’s excited about the way nature has inspired research in his lab. In his own words, “Evolution is the best problem solver.”